Theme Park Industry

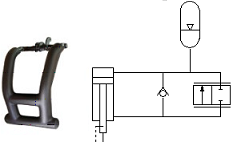

Hydraulic Lap Bar

Safety is the most important factor In the theme park industry, therefore, a lap bar for roller coasters is a must in the design. The hydraulic lap bar circuit shown in the image ensures the riders are safely secured; and the accumulator in the circuit supplies pressure when needed. In this situation, the designer will use HyPneu to simulate the load capacity in vertical or horizontal directions, as well as to apply detailed axis setups for X, Y, and Z. With the simulation component in HyPneu, the designer plots multiple failure points for ultimate safety.

Brakes and Clamps

Squeeze and fin brakes are most typical on coasters. Using pneumatics, these “clamps” are used to clench and seize the roller coaster to come to a stopping point. The reliability of these brakes is essential to the non-stop braking action utilized by the coaster during repeated operation in theme park season. HyPneu pneumatic simulation can set the preset brake pressure on certain motors and cylinders’ break away pressure and running pressure for braking applications.

Motion Simulator

Theme park machinery uses servo-controlled hydraulics for precise control of rapid and repetitive motion. When certain valves open, air (pneumatic force) acts as a cushion to accelerate the load, other than using rough hydraulic motion. HyPneu can determine the sequencing of valves, controls, and regulate the flow needed for any circuit; imperative for theme park mechanisms, due to the need of smooth transitions through valve shifting. The PLC circuit example shown is one of many ways HyPneu can create the sequence for valve controls.